24/7 Support: 400-100-9031

TEN PLASTICS

THE POLYCARBONATE SHEET MANUFACTURE

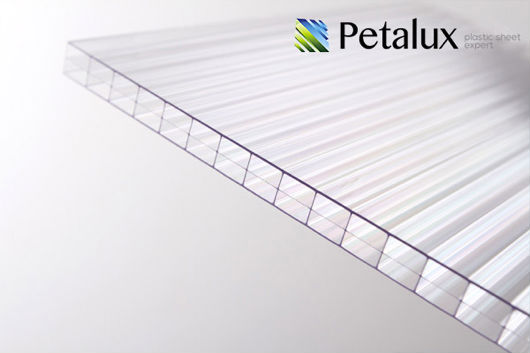

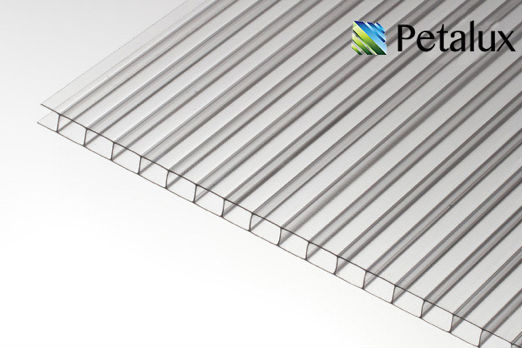

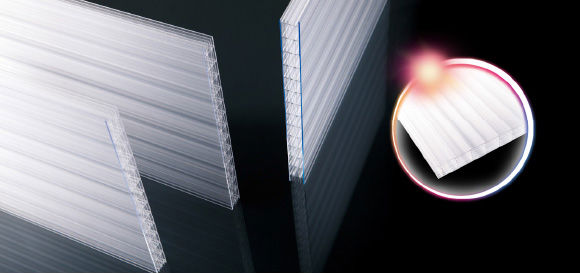

POLYCARBONATE TRIPLE WALL HOLLOW SHEET

Weight for Polycarbonate hollow sheet is comparatively light, but its strength is very good. besides, it has good thermal insulation performance. Compared to polycarbonate twin wall sheet, the Petalux™ triple wall sheet has better performance of heat insulation. It is suitable for cases that has higher requirement of temperature maintenance and envery saving. Due to our unique designs, the sheet is not getting crack while in cutting or drilling circumstances.

Petalux™ has advanced UV coextrusion technology by which to ensure that all product maintain high anti UV performance. 10 years of quality guaranteed. Petalux™ Triple wall sheet is available for thickness from 6mm-16mm

Typical Applications

Canopy/Awning/Lighting Roof/Car Parking Roof/Sky Windows/Greenhouse/Stadium/Commercial Constructions/Metro Entrance/Indoor Separations/

Product Features

• Easy to install

• High light transmission

• UV insulation

• Color Optional

• Good mechanical performance

• Good thermal insulation

• Anti dropping

• Easy to process

• High Impact Strengh

• Strong Load Capacity

PETALUX™ Polycarbonate Hollow Sheet has superb light transmission. The surface UV layer can prevent polycarbonate sheet from the aging and keep the high transmittance in the long term. UV coextrusion technology can be divided into single and double layer and applicable to all polycarbonate hollow sheet structures.

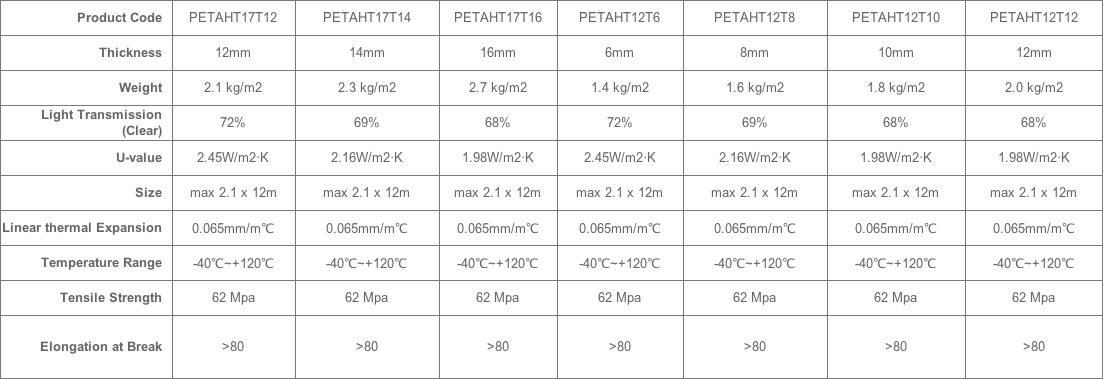

PETALUX™ Polycarbonate Triple Wall Hollow Sheet Product Data

© 2016 Ningbo Ten Plastics Co. Ltd. All Rights Reserved.

Have a Check on New design and up coming masterpiece for this year here.

Show More Details

Recent Posts

Lurabitur placerat, dui at malesu da tempus nisl est ullamco...

June 13, 2013

Lurabitur placerat, dui at malesu da tempus nisl est ullamco...

June 13, 2013

Lurabitur placerat, dui at malesu da tempus nisl est ullamco...

June 13, 2013

Recent Comments

Check out this great item 'Fabulous Parallax - Responsive One Page

June 13, 2013

Check out this great item 'Fabulous Parallax - Responsive One Page

June 13, 2013

Check out this great item 'Fabulous Parallax - Responsive One Page

June 13, 2013

Contact Us

Anti aging UV coextruded layer on surface

10 years warranty

Maitaining high coating thickness of UV and flat distributing, Petalux™ polycarbonate sheet adopts advanced multi-layer co-extrusion technology to ensure all pc sheet products from us has high light transmission rate and in applications to have at least 10 years warranty

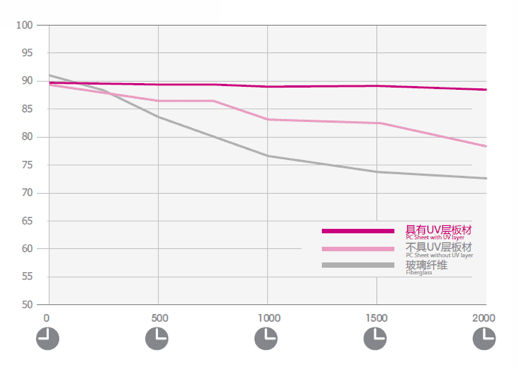

Comparison between UV and none UV polycarbonate sheet under with the UV lighting test.

Nano silicone anti-dropping coating

The new generation of PETALUX™ anti-dropping polycarbonate sheets is produced by imported hydroxyl coated nano silicone. It get coatted on polycarbonate sheet surface. This material increase vapor tension at the surface of polycarbonate sheet and its typical water contact angle can be lowered to 8 degrees. In this way, water droplets accumulated from mist get quickly dropping down along inner wall of sloping polycarbonate hollow sheets. It is suitable for lighting roof that has requirement of no water droppings,especially for swimming pools, agriculture greenhouse and ecological plant parks.

Infrared radiation control technology

Petalux™ new generation polycarbonate hollow sheet is made by special modified resin (adopting infrared barrier and metal reflector technology) in thermal control management. This make it possible that to ensure light passing through, at the same time, effectively block the infrared heat away. It significantly reduces building energy consumption costs in cooling and lighting aspect, and creates more comfortable indoor environment.

2000 hours of QUV accelerated aging test

Note:

1, 100 hours of exposure to the sun is equivalent to 1 years of exposure to outdoor UV exposure in this QUV test.

2, Sun exposure is one of the main factors to accelerate the aging process。

3, polycarbonate sheet with UV layer co-extruded, after 2000 hours of QUV accelerated ageing test, still has stable transmission rate in our test, but the one without UV has it significantly decreased.

Nano silicone anti-dropping coating

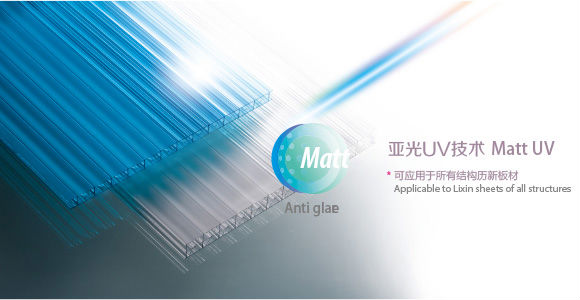

Matt UV Technology

The light pollution of modern architecture is becoming more and more serious! Matt UV is of one the unique technology from PETALUX™ polycarbonate sheet. It effectively isolates polycarbonate sheet roofs from ultraviolet radiation, and also prevents it from light reflection. It gets light more soft. At the same time, it increases the visual effect like matte surface. It can be made into a variety of personality colors that has diverse appearance.

Excellent Heat-resisting Candidate

High Temperature Resistant!

Petalux™ polycarbonate sheet is applicable in enviorment in temperature from -40oC ~ 140oC. The raw material polycarbonate resin melting point temperature is 400oC.